JMatPro®

JMatPro®

JMatPro® is a simulation software which calculates a wide range of materials properties for alloys and is particularly aimed at multi-component alloys used in industrial practice.

Full Details

JMatPro® can calculate:

- Stable and metastable phase equilibria

- Solidification behaviour and properties

- Mechanical properties

- Thermo-physical and physical properties

- Phase transformations

- Chemical properties

How it works:

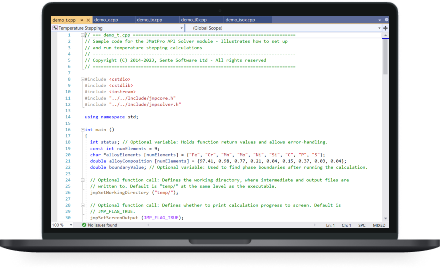

JMatPro® includes a Java based user interface, with calculation modules using C/C++, and will run under any Windows OS.

JMatPro® has been designed so that it can be used by any engineer or scientist that requires materials properties as part of their everyday work. To this end, we take great care in the following points:

- Extensive validation of the models to ensure sound predictions of the properties.

- Fast and robust calculations.

- Ease of use due to an intuitive user interface.

- Extensive on-line help facility.

Image 0/0

Resources

The documents below will give you more detailed information relating to JMatPro® features:

History

The development of JMatPro® started in 1999 and was initially funded by an international consortium of companies and institutions who were looking into extending the use of thermodynamic databases to develop the capability to predict a wide range of physical and mechanical properties for complex alloys.

Sente Software Ltd. was created in 2001 to take responsibility for the long term commercial development of JMatPro®. It now leads the development of the new scientific capabilities in JMatPro® alongside the development of its powerful graphical user interface.

All of our products combine industrial relevance with realistic physical models and user-friendly interfaces.

We have a proven track record for innovation and our products incorporate a thorough validation process.

Latest Software Releases

Please see the links below to read all about the changes made in the latest version releases of JMatPro®, the JMatPro® API and the JMatPro® Material Property Optimiser (MPO) :

VERSION 10.0

• Extended back diffusion calculations in the Solver and Solidification modules to consider user-defined cooling profiles.

• Extended the calculation of room-temperature matrix mechanical properties in Coldfire for magnesium and copper alloys.

• Extended Mechanical module for cast magnesium alloys, including the calculation of room-temperature and high-temperature strength, as well as flow stress curves.

• Extended Mechanical module for copper alloys, including the calculation of high-temperature strength and flow stress curves.

• Extended high-temperature strength and flow stress calculations in the Mechanical module for titanium alloys in the tempered condition.

• Extended the calculation of tempered hardness to consider general steels of quenched microstructure.

• Added time to the output of back diffusion calculations in the Solver and Solidification modules.

• Added the option of toggling phase boundaries search in Solidification calculations using the quench from equilibrium model, via the Solver function jmpSetPhaseBoundariesSearch().

• Added function to define the casting cooling rate used in Mechanical calculations for cast aluminium and magnesium alloys.

• Improved robustness of Scheil-Gulliver calculations with and without back diffusion.

• Improved Solidification and Cooling calculations for general steels and titanium alloys.

• Improved high-temperature strength calculations for aluminium alloys.

• Updated the thermodynamic and properties databases to match those included in JMatPro v16.0.

• Added Ta and B to stainless steels.

• Added Co and S to copper alloys.

• Added BN, M3B2, MB2_C32, CR2B, FE2B, and FE3B phases to stainless steel thermodynamic database.

• Added CO_HCP, CO_FCC, and CU2S phases to Cu thermodynamic database.

• Adjusted physical properties databases.

• Fixed possible failure in Cooling calculations when setting multiple constant cooling rates.

• Fixed possible issue in Cooling calculations for general steels with user-defined cooling profiles.

• Fixed possible issue in Cooling calculations for fully martensitic titanium alloys.

• Fixed possible issue in the high-temperature strength of tempered general steels with lean compositions.

• Fixed possible issues in strength calculations for aluminium alloys.

• Fixed possible failure in creep calculations for nickel alloys and addressed inconsistency issues with rupture calculations.

• Fixed possible failure in Heat Treatment calculations for nickel and nickel-iron based superalloys.

• Fixed small inconsistencies in TTT calculations for general steels.

• Fixed small renormalisation issues for titanium and copper alloys when secondary phases are present.

VERSION 16.0

NEW FEATURES

• optimised all calculations for more speed

• added the possibility to use user defined solidification profiles in the solidification of Al, Mg, Ti, Co, Ni, Zr alloys and General/Stainless Steels (linked to back-diffusion)

• added possibility to use any quenched microstructure in the Tempered Hardness calculation of General Steels

• added Simultaneous Precipitation calculation for austenitic Stainless Steels

• added High Temperature Strength and Flow stress calculations to Cu alloys

• added High Temperature Strength and Flow Stress calculations to cast Mg alloys

• added possibility of tempered condition in High Temperature Strength and Flow Stress calculations to Ti alloy

• more rigorous Solidification and Quenching calculations for General Steels

• more advanced model for Simultaneous Precipitation in General Steels

• advanced TTT calculation for Ti alloys

• improved calculation of High Temperature Strength calculation for Al alloys

• adjusted solidification and cooling properties calculations for Titanium alloys

• more robust back-diffusion calculations

• added time axis in solidification graphs when relevant

• fixed failing calculations at highest temperatures in High Temperature Strength when temperature fixed

• added sanity check on time in user defined cooling/solidification/... profiles

• extended model for grain size evolution in Multi-Pass Hot Rolling calculation for General Steels

• extended model for grain size evolution in Multi-Pass Hot Rolling calculation for General Steels

• many small changes in the GUI

DATABASE CHANGES

• added element Ta and B to Stainless Steels thermodynamic database with phases BN M3B2 MB2_C32 CR2B FE2B and FE3B

• added Co and S to the Cu alloys thermodynamic database with phases CO_HCP, CO_FCC and CU2S

• adjustments in the physical properties databases

EXPORT CHANGES

• added Transformation Plasticity Coefficients to export to DEFORM-HT

• improved and extended SYSWELD and PROCAST export

• improved Transvalor SIMHEAT Nitriding export

• added Cu alloys export to FORGE, THERCAST, DEFORM, QFORM, Abaqus and Simufact

• added Mg cast alloys export to FORGE, THERCAST, DEFORM, QFORM, Abaqus and Simufact

• improved Ansys Workbench export (strain unit + 100 points limit)

• added hardness column to Transvalor for Steel export

• fixed default export settings for QFORM-HT

BUG FIXES

• fixed issue in Sysweld export introduced in v15

• fixed potential failures in several calculations linked to the use of a new compiler version

• fixed potential issue using a user defined time-temperature cooling profile for General Steels

• fixed potential issues for Al and Mg alloys strength calculations

• fixed potential issue in Titanium Cooling Properties if no Alpha present but all Martensite

• fixed potential issue with the High Temperature Strength of a General Steel in tempered state when lean composition

• fixed potential failure in Nickel alloys Creep calculation and consistency with rupture calculation

• fixed potential failure in Nickel alloys Heat Treatment calculation

• fixed small inconsistencies in the General Steels TTT calculations

• fixed small renormalisation issues in Ti and Cu alloys when secondary phases are present

• fixed potential issue with the automatic calculation of cooling rate for General Steels properties export to third party packages

• fixed inaccuracy for grain size of Stainless Steel used in High Temperature Strength calculation

• fixed sanity check of user defined cooling profiles

• fixed possible missing specific heat points in General Steels Quench Properties plots

• fixed back-diffusion not used in Homogenisation calculation

• fixed display of cooling profile plots for Homogenisation calculation

VERSION 9.1

- Extended TTT and CCT modules for stainless steels, nickel and nickel-iron based superalloys, single crystals, as well as aluminium, magnesium, cobalt, titanium, and zirconium alloys

- Extended Mechanical module with the calculation of flow stress per phase for general steels

- Moved jmpSetPhasesCheck() to the Core module

- Updated Python sample code to run on version 3.12

- Fixed memory deallocation mismatch causing a crash when running sequential Solver calculations

- Fixed missing microstructure labelling causing a crash in flow stress calculations for stainless steels

- Fixed material type labelling for consistency in heat treatment calculations for nickel-iron based superalloys

VERSION 9.0

- Extended the calculation of physical, thermophysical and mechanical properties below room temperature

- Added Heat Treatment module for the calculation of microstructural evolution and room-temperature strength following heat treatment of nickel and nickel-iron based superalloys

- Added secondary phases in the calculation of CCT diagrams of general steels, including the contribution of carbides to the strength

- Extended the calibration of TTT/CCT diagrams of general steels to include shifts in bainite and martensite start temperatures

- Added atomic and weight phase fractions to the output of cooling and quench solidification calculations

- Added magnetic permeability to the output of cooling and quench solidification calculations for general steels

- Added phase boundaries search in Solidification calculations using the quench from equilibrium model

- Improved robustness of automatic extraction of austenitisation temperature in quench solidification calculations for general steels

- Extended high-temperature strength and flow stress calculations in the Mechanical module for stainless steels in the tempered condition

- Improved flow stress calculations for general steels in the tempered condition

- Extended the calculation of tempered hardness to consider general steels of martensitic, bainitic and pearlitic microstructures

- Changed high-temperature strength calculation strategy to make sure output respects user choice of maximum temperature

- Improved phase mapping to deal with hanging and labelling issues

- Changed stacking-fault energy calculation to prevent negative values

- Updated the thermodynamic and properties databases to match those included in JMatPro v15.0

- Added Nb to aluminium alloys

- Added Ti to copper alloys

- Added Si3N4 phase to Fe thermodynamic database

- Adjusted (Fe,Ni)Al phase in Fe thermodynamic database

- Added Cu4Ti and CuNiTi phases to Cu thermodynamic database

- Reassessed AlCuFeNi systems in the Cu thermodynamic database

- Adjusted Mo in LAVES phases in Ni and Co thermodynamic databases

- Adjusted Ni and Co in FCC contribution to molar volume

- Extended properties of SiC phase

- Fixed possible failure in Solidification calculations using the quench from back diffusion model for steels, when ferrite fully transforms to austenite in a single temperature step below the solidus

- Fixed possible failure in Solidification calculations for heavily alloyed titanium alloys

- Fixed possible failure in high-temperature strength calculations

Version 15.1 (January 2025)

BUG FIXES

fixed missing enthalpy, specific heat and latent heat in solidification export for Titanium alloys

- fixed a heat treatment temperature initialisation issue in General Steels high/low temperature strength calculation when switching from tempered state back to the annealed state

Version 15.0 (November 2024)

NEW FEATURES

- added choice between martensitic, bainitic and pearlitic microstructure in the tempered hardness calculation for General Steels

- added secondary phases consideration in Advanced CCT and Hardenability calculations for General Steels

- added calculation of physical and mechanical properties under room temperature for all materials

- added calculation of magnetic permeability in General Steels Quench Properties

- added choice between annealed and tempered condition in High Temperature Strength for Stainless Steels

- added new variable Bar Radius in Grossmann hardenability of General Steels

- added display of weight fractions in back diffusion profile plot

- added an expert mode in options for user settings

- added Bainite and Martensite start temperature to calibration of General Steels TTT

- added a warning message about using high transformation fractions in General Steels Quick TTT/CCT

- more robust General Steels solidification calculation if only Ferrite is present in the mushy zone

- more robust General Steels and Stainless Steels solidification calculation

- more robust Heat Treatment calculation for Ni alloys

- improved axis labelling in General Steels hardenability plots

- improved label for High Temperature Strength plots

- improved strength conversion in input for High Temperature Strength calculation of Stainless Steels

- improved consistency in Ni Superalloys "Heat Treatment" calculation for alloys containing Boron

- improved appearance of list of properties when folding properties' groups

- improved stress-strain calculation for High Temperature Strength in tempered General Steels

- improved phases mapping in isopleth calculations

- improved cast strength calculation for Mg alloys

DATABASES CHANGES

- overall check and clean-up of all thermodynamic databases (Fe,Al,Mg,Ni,Co,Cu,Ti,Zr and Solder Alloys)

- new assessment of AlCuFeNi systems in Cu thermodynamic database

- addition of Si3N4 phase to Fe thermodynamic database (for SIMHEAT export use)

- addition of Nb to the Al thermodynamic database

- addition of Ti to the Cu thermodynamic database with phases Cu4Ti and CuNiTi

- adjusted (Fe,Ni)Al phase in Fe thermodynamic database

- adjusted Mo in LAVES phases in Ni and Co thermodynamic databases

- adjusted Ni and Co in FCC contribution to molar volume

- extended properties of SiC phase

EXPORT CHANGES

- new AFDEX heat treatment export

- improved Transvalor-Steel and THERCAST export for hypereutectoid steels

- added hardness data to DEFORM-HT export

- improved SIMHEAT nitriding and carbo-nitriding export

- added option of non-treatable alloys in Sysweld export for Aluminium Alloys

- removed potential double point in Sysweld export for Aluminium Alloys

- changed the order in temperature of physical properties order in DEFORM-HT/DEFORM-Forming to avoid data interpolation issues

- corrected unit of electrical conductivity in export to COMSOL-Multiphysics

- extended phase transformations and magnetic permeability in COMSOL-Multiphysics export

- added an option to only export small strain points in General Steels export to Heat Treatment packages

BUG FIXES

- fixed potential saving of un-calibrated data to a calibrated General Steels material file

- fixed calculation of Al cast strength T5 temper

- fixed Flow Limit Diagram calculations for Co alloys

- fixed a potential failure in High Temperature Strength calculation

- fixed export options not all shown under certain conditions

- fixed phases colours choice not respected in General Steels hardenability plot

- fixed potential failure in solidification calculation for heavily alloyed Ti alloys

- fixed ASTM grain size use in Austenite flow stress in General Steels

- fixed limit of graph to the maximum temperature chosen instead of the heat treatment temperature in High Temperature Strength and Flow Stress Analysis of Ni,Ti,Co alloys and Stainless Steels

- fixed failing calculation of TTP for Stainless Steels and General Steels

- fixed wrong grain size indication in the results of room temperature strength of Ti alloys if only Beta is present

- fixed input window getting too large

VERSION 2.1 (November 2024)

- Fixed casting route calculations for stainless steels

- Added check to prevent running calculations for pure elements

- Updated terms and conditions

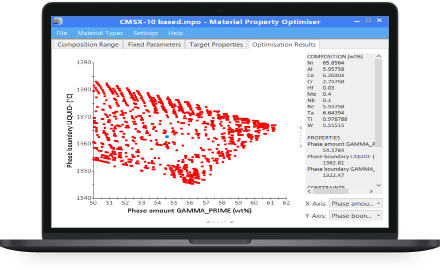

VERSION 2.0 (September 2024)

- Extended design space to include processing variables: heat treatment temperature, austenitisation temperature, cooling rate, and holding temperature/time

- Implemented calculation of mechanical properties for aluminium alloys, general steels, and Ni- and NiFe-based superalloys

- Added a casting route for the calculation of thermodynamic and physical properties

- Added new module "Cast Iron"

- Extended objective space to include many more properties: average expansion coefficient, solidification range, hot cracking susceptibility, growth restriction factor, room-temperature yield stress, tensile stress, and hardness, rupture stress/life, average bond order and orbital energy level

- Further extended objective space to include user-defined properties as a function of temperature and alloy composition

- Updated the thermodynamic and properties databases to match those included in JMatPro v14.0

- Fixed a minor bug preventing some popup components from working properly

Version 2.0 (September 2024)

CHANGES

- Extended design space to include processing variables: heat treatment temperature, austenitisation temperature, cooling rate, and holding temperature/time

- Implemented calculation of mechanical properties for aluminium alloys, general steels, and Ni- and NiFe-based superalloys

- Added a casting route for the calculation of thermodynamic and physical properties

- Added new module "Cast Iron"

- Extended objective space to include many more properties: average expansion coefficient, solidification range, hot cracking susceptibility, growth restriction factor, room-temperature yield stress, tensile stress, and hardness, rupture stress/life, average bond order and orbital energy level

- Further extended objective space to include user-defined properties as a function of temperature and alloy composition

- Updated the thermodynamic and properties databases to match those included in JMatPro v14.0

- Fixed a minor bug preventing some popup components from working properly

Version 8.1

Implemented a more efficient algorithm to accelerate the calculation of flow stress curves.

Improved calculation of the elastic limit point in stress-strain curves.

Improved model and fixed inconsistencies in strength calculations for aluminium alloys.

Version 8.0.1

- corrected typo in parameter for mechanical properties of some Aluminium alloys

Version 8.0

- Implemented a back diffusion model for steels in the Solver and Solidification modules.

- Extended the Solidification module with a quench from back diffusion model for steels and titanium alloys, improved existing quench models, and implemented a variant of the quench from Scheil-Gulliver model for titanium alloys.

- Added specific heat and latent heat of formation for each of the austenite decomposition products to the output of a Solidification calculation using the quench from Scheil-Gulliver model for steels and white cast irons.

- Extended the Cooling module for titanium alloys.

- Extended high-temperature strength and flow stress calculations in the Mechanical module for general steels in the tempered condition.

- Improved calculation of latent heat of formation of ferrite from austenite.

- Reassessed creep for BCC phase in steels.

- Improved creep and rupture strength models for nickel-based alloys.

- Added new dislocation cutting mechanism in aluminium alloys kinetics.

- Remodelled age hardening for Al3Sc phase in aluminium alloys.

- Improved stability of the thermodynamic solver.

- Updated the thermodynamic and properties databases to match those included in JMatPro v14.0.

- Adjusted the Al thermodynamic database.

- Reassessed molar volume of Ti2Cu and Ti2Ni phases for titanium alloys.

- Fixed possible failure in aluminium strength calculations.

- Fixed possible failure in high-temperature strength calculations for general steels.